Material composition is critical to a material's machinability, durability and stability in its intended use. As products have persified, we've seen a surge of new alloys, coatings, polymers and emerging materials including fiber-reinforced composites and ceramics. Manufacturers are constantly developing lighter, stronger and more heat, chemical and exposure resistant alloys/materials designed to meet a variety of specific end uses. These may include renewable or recycled materials, making composition and material properties more challenging to control.

A strict quality system involves chemical analysis to verify chemical composition from raw material to finished product. This ensures a safe, high-quality product that will meet your customer's needs.

Antimony Analysis (ICP)

Ash Content

Cadmium Analysis (ICP)

Carbon, Sulfur, Hydrogen, Oxygen, Nitrogen

Coating Weights

Coefficient of Thermal Expansion

Conductivity (ASTM D1125)

Contamination ID

FTIR

GC/MS (Thermal Desorption, Pyrolysis)

Halogen Analysis (IC)

Heavy Metals Analysis

Hex Chrome (UV-VIS)

ICP-AES Analysis

Impurities Analysis

Ion Chromatography

Metal Purity

Particle Size Analysis

pH

Polymer Testing

Powder Diffraction

Powdered Metal Analysis

Precious Metal Assay

Quantitative Analysis

RoHS Testing

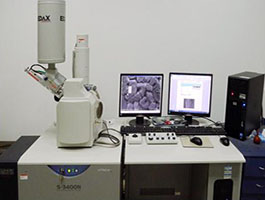

SEM-EDS

Semi-Quantitative Analysis

Sieve Analysis

TD/GC/MS (Thermal Desorption)

Trace Element Analysis

Unknown Alloy Identification

Unknown Material Identification

XRD Analysis